(815) 436-7077

info@HarvestEngineering.com

Spray Pattern Analysis

Unique Virtual Target Displays Pattern Geometry

Production Environment Pass Fail Capabilities

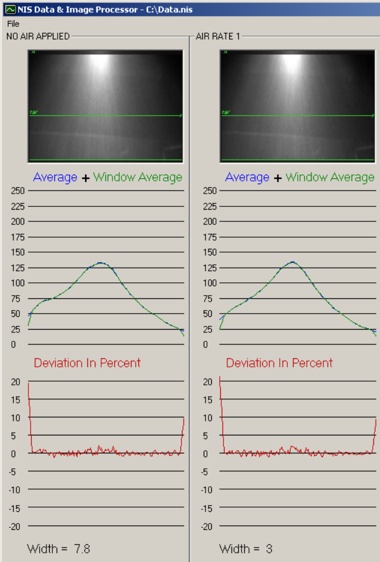

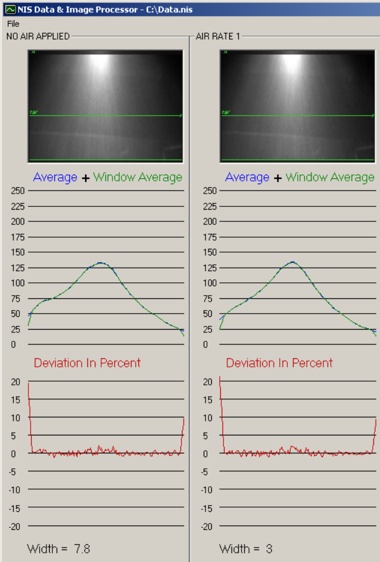

Typical Output From Spray Pattern Analysis Software

Free Evaluation

Let Harvest Engineering LLC. demonstrate the capabilities of the spray pattern

analysis system using one of your nozzles. Just provide us with

a nozzle and the appropriate holder and in a short time we’ll

send the results to you. Contact us first with the requirements

for your type of nozzle. Without any obligation you can find out

if our system is right for you.

Complete lab systems or production line units

Lab systems include a downdraft chamber that allows the user to

view clear, live images while capturing test data. Production line

analyzers can provide fast PASS / FAIL information based on spray

densities or pattern geometry while accommodating pick and place or

other automated equipment.

Relative density &

pattern geometry

pattern geometry

Relative density shows the distribution across the entire pattern.

Easily identify and record voids and hot spots. The unique virtual

target displays pattern geometry by a acquiring a cross section image

without disturbing the spray. Quickly reject nozzles that are out

of bounds.

Interface & Analysis

Presets may be saved and recalled making setup easy for

production personnel. Test data, including images, may also be

archived. The data is ready to be imported into your database or

spreadsheet for quality assurance or for performing custom

analysis. Standard Ethernet connectivity facilitates setup and

data collection for production units.